Optimizing with Precision

Lean Manufacturing, paired with Six Sigma, transforms production by eliminating waste and optimizing quality. Lean’s focus on flow leverages tools like Line Balancing, Value Stream Mapping, and Total Productive Maintenance, while Six Sigma’s data-driven approach enhances process control through DMAIC problem-solving. Supported by GEMBA walks and Three-Tier Management with KPI war rooms, this integrated methodology drives continuous improvement, reduces costs, and ensures consistent, high-quality output that meets customer demands with precision.

Enhanced Process Efficiency

Line Balancing and Value Stream Mapping eliminate bottlenecks, ensuring seamless production flow.

Six Sigma Quality

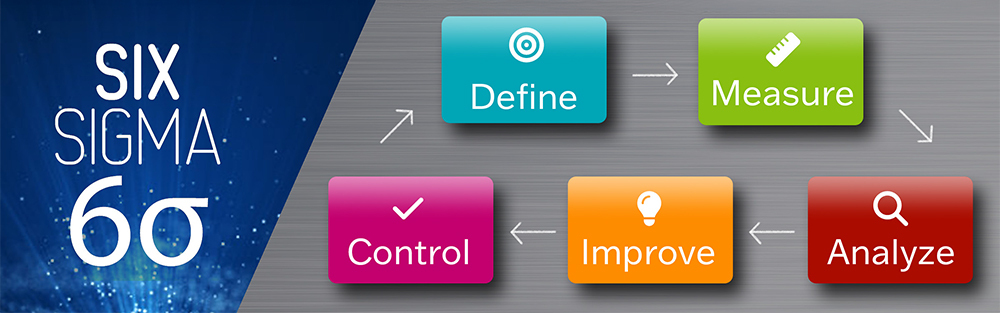

Six Sigma’s DMAIC methodology minimizes defects and variability, delivering reliable, high-quality results.

Real-Time Accountability

GEMBA walks, Three-Tier Management, and KPI war rooms provide visibility and align teams on key performance metrics.

Key Lean Manufacturing Tools

• Line balancing

• Value Stream Mapping

• Total Productive Maintenance

• DMAIC problem solving

• GEMBA boards/ walks

• Three tier management and establishment of KPI war rooms

• Kaizen Events